Slinguri: Simple Guide to Baby Slings and Fishing Slings

The word slinguri has two common meanings in Romania.

-

For parents, it means baby slings – soft fabric carriers that hold babies close.

-

For anglers, it means fishing slings – special bags that help weigh and release fish safely.

This guide explains both kinds in simple words.

Baby Slings (Slinguri pentru bebeluși)

What Is a Baby Sling?

A baby sling is a piece of cloth that helps parents carry their baby close to the body. Some use rings, some are sewn into loops, and some are just long wraps. Baby slings make carrying easier and keep babies safe and close.

Types of Baby Slings

| Type | How It Works | Best For |

|---|---|---|

| Ring Sling | Long cloth goes through 2 rings, can be tightened easily | From newborns to toddlers, short trips |

| Pouch Sling | Pre-sewn loop of fabric, quick to wear but not adjustable | Older babies, quick use |

| Wrap Sling | Very long fabric, tied around the body in many ways | Newborns, long wear |

| Double / Hybrid Sling | Two straps or a panel, more support | Babies 4–18 months |

Why Parents Use Baby Slings

-

Baby feels safe and close

-

Parent has hands free

-

Can breastfeed quietly

-

Good for baby’s hips and back (M-position)

-

Baby often cries less

Safety Rules for Baby Slings

-

Baby’s chin must not touch chest

-

Baby’s face must be visible

-

Baby’s back supported

-

Baby’s knees higher than bottom

-

Sling must feel snug, not loose

How to Use a Baby Sling (Step by Step)

-

Prepare – Adjust rings or wrap fabric before placing baby.

-

Put Baby In – Position baby upright or sideways depending on age.

-

Tighten – Pull fabric in small sections to make it snug.

-

Adjust – Spread fabric wide over shoulder and back.

-

Check – Make sure baby can breathe and feels comfortable.

How to Choose the Right Baby Sling

-

Material:

-

Cotton = breathable

-

Linen = strong

-

Bamboo = soft

-

-

Baby’s Age: wraps are good for newborns, pouch or double slings work for older babies.

-

Parent’s Needs: quick and easy (ring sling) vs. long but comfy (wrap).

-

Ethics: some parents prefer handmade or eco-friendly slings.

Read also: 4 Top-Class Bridal Belts in 2025

Care and Cleaning

-

Wash in machine (rings inside a bag if possible).

-

Break in fabric by using it, braiding, or ironing lightly.

-

Store dry to avoid mold.

Common Problems and Fixes

-

Fabric slips through rings → Re-thread slowly.

-

Sling feels uneven → Tighten section by section.

-

Shoulder hurts → Switch shoulders or spread fabric more.

Fishing Slings (Slinguri pentru pescuit)

What Is a Fishing Sling?

In fishing, a sling is a bag made of mesh used to weigh and release big fish, like carp. It protects the fish and makes weighing safe.

Main Features of Fishing Slings

| Feature | Why It Helps |

|---|---|

| Soft Mesh | Keeps fish safe, no scale damage |

| Handles | For easy and safe lifting |

| Zippers | Hold fish inside securely |

| Floatation Bars | Let sling float on water |

| Large Size | Can hold fish up to 50 kg or more |

| Carry Bag | Easy to fold and move |

Why Anglers Use Fishing Slings

-

Protects fish skin and scales

-

Makes weighing easy and fair

-

Supports catch and release fishing

-

Many fishing lakes require slings by rule

How to Use a Fishing Sling (Step by Step)

-

Wet the Sling – Keeps fish safe.

-

Place Fish Inside – Support carefully, don’t drop.

-

Weigh Fish – Attach sling handles to scale.

-

Release Fish – Put sling in water, open zippers, let fish swim away.

How to Choose the Right Fishing Sling

-

Fish Size – Large carp need deeper slings.

-

Durability – Look for strong zippers and thick stitching.

-

Travel – Compact folding slings are good for trips.

-

Rules – Some places only allow certain sling types.

Popular Fishing Sling Options

-

Decathlon Caperlan Sling – Lightweight, foldable, holds up to 50 kg.

-

Fox or Trakker Carp Slings – Premium brands, floatation bars, extra depth.

-

Multi-Use Slings – Can hold fish in water before weighing.

Ethics in Fishing

Fishing slings show respect for nature. They help fish survive after release and allow anglers to enjoy fishing without harm.

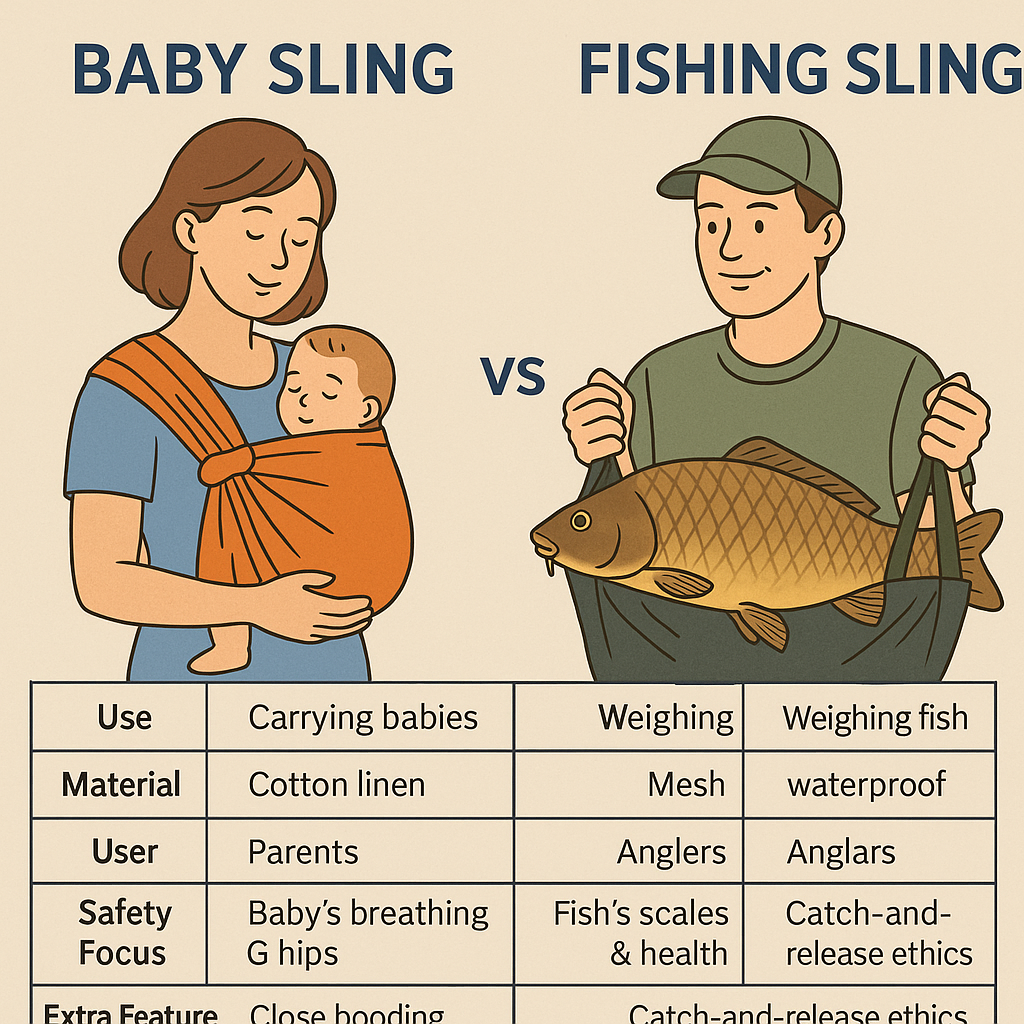

Baby Slings vs. Fishing Slings

| Feature | Baby Sling | Fishing Sling |

|---|---|---|

| Use | Carrying babies | Weighing fish |

| Material | Cotton, linen, bamboo | Mesh, waterproof |

| User | Parents | Anglers |

| Safety Focus | Baby’s breathing & hips | Fish’s scales & health |

| Extra Feature | Close bonding | Catch-and-release ethics |

Conclusion

The word slinguri means different things, but in both cases it’s about care and safety.

-

For parents, baby slings make life easier, keep babies close, and help them grow safe and happy.

-

For anglers, fishing slings make sure fish are weighed and released without injury.

Whether for a baby or a fish, slinguri are about holding life gently and responsibly.