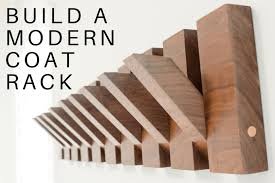

How to Build a Modern Coat Rack

I am now accepting custom order for the Modern Coat Rack HERE Check out the “How to Build a Modern Coat Rack” video here

Step 1: Select your materials

I decided on some air-dried walnut that I had been holding onto for a long time. However, you could choose pretty much any wood for this project. Even plywood would probably make a great modern coat rack design.

Step 2: Cut and dimension your lumber

If using rough lumber, cut it to the length you want your coat rack and proceed to joint and plane the wood. If you purchased pre-surfaced lumber than go ahead and cut to length and width. I made my coat racks 30″ long to fit in the space I had, but you could make them any length.

Step 3: Cut your board into sections

I cut 2″ strips for the stationary pieces and 1″ strips for the moveable pieces that will be used for hanging. Again you could use a variety of different measurements for this, so don’t be hung up on the 1″ and 2″ strips. You can experiment here to see what works and looks best for your own modern coat rack.

Step 4: Cut the angles on the moveable pieces

Here is where you cut the angles on the pieces that will fold out to be the hangers in your modern coat rack. You don’t technically need the angle on the top but I think it helps and looks better. I cut 45 degree angles on both ends but ended up having to go back and trim a little more off the bottom so it could swing all the way down without rubbing the wall. Check out the video to see what I’m talking about.

Step 5: Drill each piece for the dowel rod

I used a 3/8″ Oak dowel rod to connect my modern coat racks. Again, this is up to you on what size and material you want to use for your dowel rod. You could match the material so it blends in or go with a contrasting color wood like I chose. I set-up stop blocks on my drill press to make the repeatable holes go a little quicker. To know where to drill I lined up the moveable piece against the side of one of the stationary pieces and traced where they met when the moveable piece was folded down. I then found the center of these marks that would serve as the axis for the dowel rod. Once you have this mark, just set-up stop blocks on a drill press or use a hand drill to drill all of your holes.

Step 6: Sand and finish all of the pieces

Next you want to sand each individual piece and finish them before assembling. I just put my random orbital sander in my bench vise and sanded each piece, you could do this by hand if needed. After sanding up to 220 grit, it was time to apply finish. I chose Minwax Wipe-on Poly, but would probably try simple Boiled Linseed Oil next time to avoid the film finish that I’m sure will show wear on these over time.

Step 7: Assembly

After the finish dries you are ready to add all of the pieces for your modern wood coat rack to the dowel rod. This proved a little difficult for me until I used a little paste wax on the dowel to lube things up. After assemble it is a good ides to use a long clamp to apply some pressure to make sure all of the pieces are seated well. Next I removed the two end pieces, added some wood glue, and reinstalled them. That’s it, the other stationary pieces did not need glue because of the tight fit and the way they mount to the wall not allowing for any movement. Once the glue is dry, flush cut the dowel ends off. Then I figured out where I wanted my mounting locations and routed key hole slots into the backs of the coat racks. Be sure only to route these into the stationary pieces!

Step 8: Install and enjoy your Modern Coat Rack

I used a screw on each end and one in the middle to mount these with the key hole slots. These coat racks have proved to be even more functional and good looking than I originally pictured! I hope this helps you build a modern coat rack of your own!

If you enjoyed this tutorial, please share on Pinterest and other social media sites as well as subscribe to my YouTube Channel. You may also enjoy some of my other project tutorials and the list of Tools from my Shop. Thank you!